Value chain activities

- Identify your product value chain

- Strategy & organisation

- Upstream supply chain

- Own manufacturing

- AkzoNobel: Measurement and follow up of own operations

- AkzoNobel: Code of conduct

- AkzoNobel: Eco-efficiency assessment to evaluate production alternatives

- SCA: Olawa factory is powered by nature

- SCA: Environmental management system

- SCA: Resource management system (RMS)

- SCA: Occupational health and safety

- SCA: Chemical assessments

- Customers and consumers

- Develop more sustainable products

- End-of-life of products

- Other stakeholders

Eco-efficiency assessment to evaluate production alternatives

In order to evaluate the effects on the sustainability performance that an possible change in production would lead to Eco-efficiency assessment (EEA) can be used. In the assessment the possible new alternative production route is compared with the current production route.

An example on when Eco-efficiency was used for evaluating this follows here:

The goal of the assessment was to evaluate the sustainability of alternative ways to supply a pulp mill with the chemicals required for production of ECF bleached pulp.

Procedure: The assessment started with gathering of data on use of raw materials and utilities, amount of waste and emissions for the alternative production routes and the production costs for each route. In parallel, the systems were modelled in the eco-efficiency tool. The first preliminary results were presented for the project team and after some additional work the final assessment results were presented for the management team.

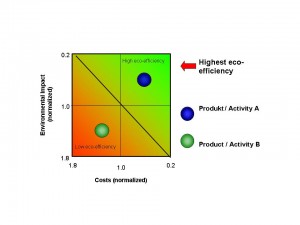

Results: The final assessment result was presented in an Eco-efficiency diagram. See example of such a diagram in the picture to the right. In addition, the total environmental impact of the four alternative production systems were analyzed more in depth and likewise the costs.

See example of such a diagram in the picture to the right. In addition, the total environmental impact of the four alternative production systems were analyzed more in depth and likewise the costs.

Experiences of the assessment: Much was learned and the study served well as a screening. The way electricity is produced was concluded to have a tremendous influence on the results and conclusions. To implement this way of working in the process development, a tailor made tool was created as part of a master of science thesis that was finalized in October 2010.